| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | SZOMK |

| Model Number : | HEM01 |

| Certification : | ISO9001:2015, SGS |

| Price : | Negotiable |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability : | 10000piece per day |

| Delivery Time : | 5-30working days |

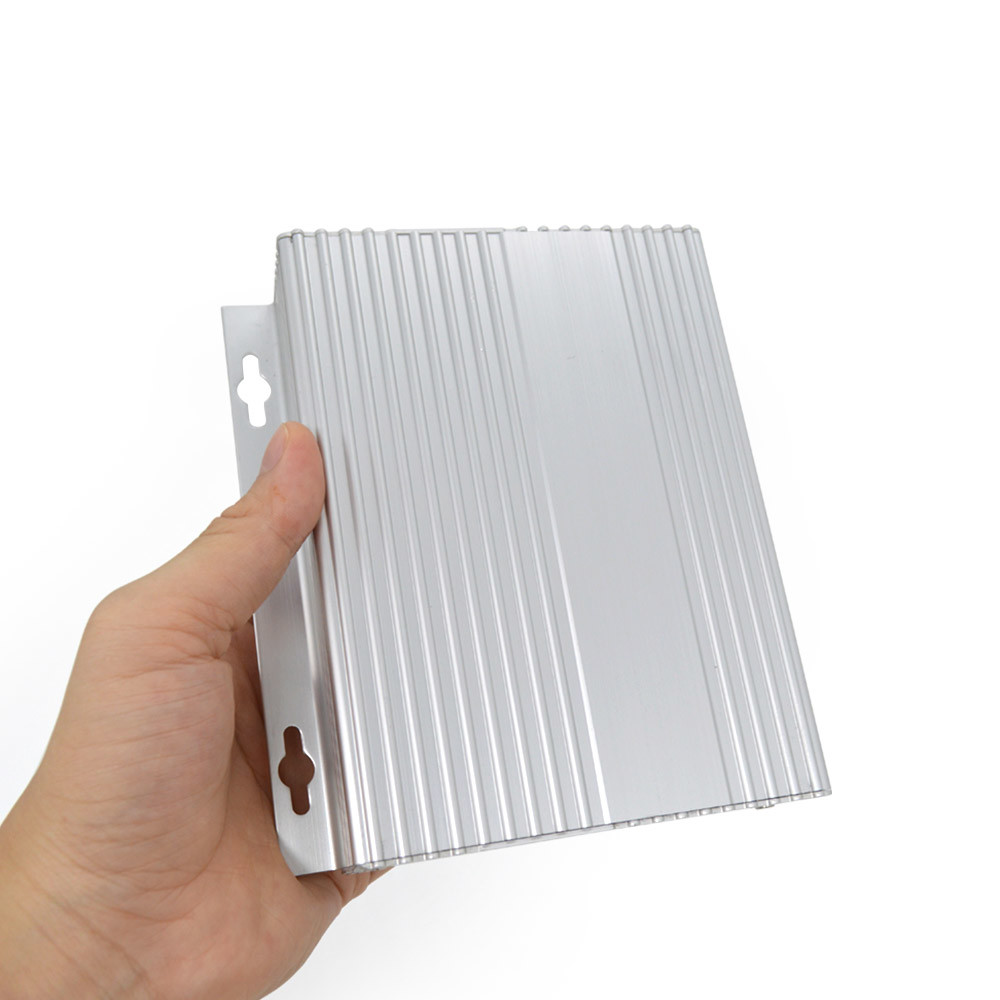

Anodized Aluminium Extrusion Molding Process Junction Box Electronic PCB Housing

Description:

Our product - extruded aluminum profiles, is a high-strength, lightweight, corrosion-resistant, and thermally stable metal material. We use advanced extrusion technology and high-quality aluminum alloy raw materials to produce aluminum profiles with precise dimensions, excellent surface quality, and various complex cross-sectional shapes. These products are widely used in industries such as construction, transportation, machinery, power, electronics, etc., providing customers with efficient, environmentally friendly, and energy-saving solutions. We can also customize production according to customer needs, meeting different requirements in terms of material, color, surface treatment, etc. Whether it is ready-made profiles or customized profiles, we meet the needs of customers with high-quality products and thoughtful services, and have won widespread market recognition.

Application:

Lamp holder

piping system

electrical equipment

medical equipment shell

engineering machinery

storage tank

lamp body

radiator

| Name | Extrusion Molding |

| Material | Aluminum,Copper,Steel,or other metal you want |

| Service | Assembly, spraying, electroplating, bending, design support, shearing |

| Logo | Silkscreen Printing, Laser Engraving, UV Printing |

| Design Software | 3D&2D |

| Drawing Format | PDF,CAD,JPG etc. |

| Customization | Drill Holes, Silkscreen Printing,Laser Engraving,CNC etc. |

| Lead Time | 1-5 working days |

| Assembly & Test | Professional assembly and testing factory |

| Payment Details | T/T, L/C, D/A, D/P, Western Union, MoneyGram, Veem, Paypal etc |

| Shipping Way | By Courier DHL, Fedex, TNT, UPS, EMS, By Sea, By Air |

| Standard | ISO9001:2015, SGS |

Advantage:

We have strong design capabilities and can independently design and

develop new products, as well as make improvements according to

customer needs, allowing you to have exclusive products.

We introduce new technologies, products, and processes to

continuously innovate and improve the core competitiveness of the

enterprise, allowing you to have more high-end products.

Strictly control quality at every stage to ensure that products

meet high standards and are worthy of your trust.

We provide customers with complete pre-sales, during sales, and

after-sales services, making them feel professional and

considerate.

Our brand has a certain level of popularity and reputation in both

domestic and international markets, and enjoys a good reputation

and reputation.

Our production capacity is strong, with multiple production lines

that can produce multiple orders simultaneously, ensuring timely

delivery of large demand.

FAQ:

Q:What are the materials used in the molds you produce?

A:We use high-quality steel, alloy steel, hardened steel and other

materials to make molds.

Q:What is the production cycle of the mold?

A:The production cycle usually takes 2-4 weeks depending on the

size, shape, and complexity of the mold.

Q:Do you accept customer customization requirements?

A:Yes, we can customize the production of molds according to

customer requirements.

Q:What is the price of the mold?

A:The price of molds is influenced by multiple factors, such as

material, size, complexity, etc. You can provide us with relevant

information and we will provide you with the most favorable

quotation.

Q:What is the lifespan of the mold?

A:The lifespan of a mold is influenced by factors such as usage

frequency, mold material, and processing materials. Generally, our

mold lifespan can reach over 50000 cycles.

Q:What metal extrusion molds do you provide?

A:We can provide customers with extrusion molds for various metals

such as aluminum, copper, iron, magnesium, zinc, titanium,

zirconium, etc.

|