| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | SZOMK |

| Model Number : | HSI01 |

| Certification : | ISO9001:2015, SGS |

| Price : | Negotiable |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability : | 100 piece per month |

| Delivery Time : | 15-30 working days |

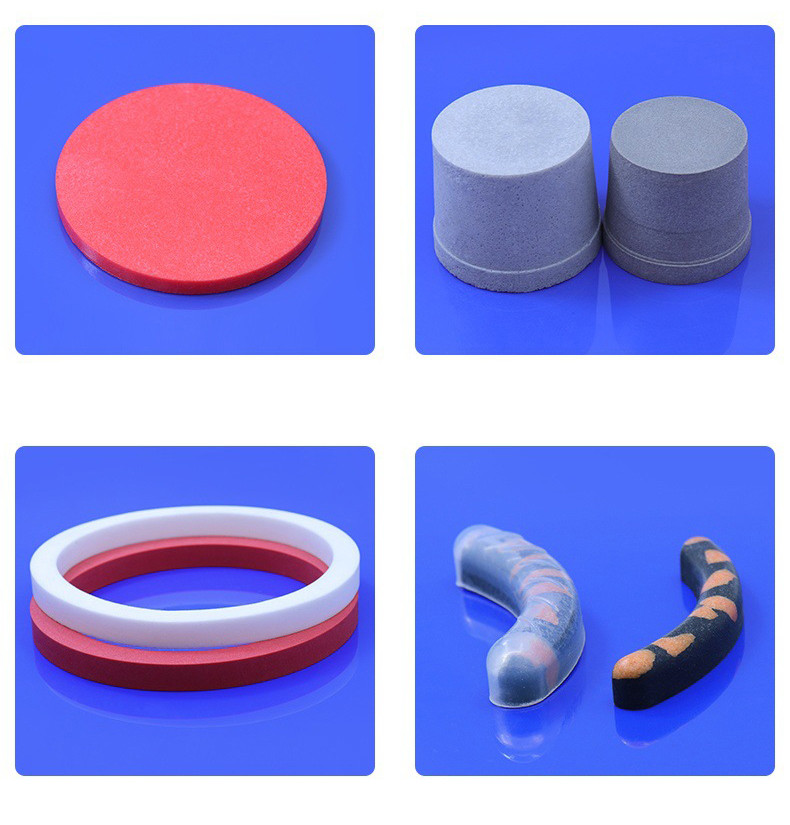

Food Grade Silicone Injection Molding Liquid Rubber Irregular Parts

Description:

Silicone is a material with high elasticity, wear resistance, and high temperature resistance, which is very suitable for making molds for various spare parts and products. Silicone rubber molds mainly have good flexibility and plasticity, and can accurately represent details and shapes when replicating prototype models, making them an ideal tool for producing high-precision products.

Application:

automotive sealing rings

Medical devices

transmission pipes

bracelets

fittings

syringe gaskets

Features:

| Name | Silicone Injection Molding |

| Material | PDMS, FVMQ, LSR, HTV, MQ, CR |

| Service | Laser engraving, plastic electroplating, membrane keyboard, RFI/EMI shielding coating, Change Material UL94-V0, silkscreen printing, acrylic plate, sticker, high-temperature retardant, ultrasonic welding |

| Design Software | 3D&2D |

| Drawing Format | step, stp, igs, dwg, prt, pdf, stl(for 3D print),etc. |

| Production Ability | 100000piece per month |

| Lead Time | 30-40 working days |

| Assembly & Test | Professional assembly and testing factory |

| Package | Wood case, standard carton, pallet or customized |

Advantage:

Being able to customize according to customer needs: We understand that customers' needs are diverse, so we can customize according to their special needs to ensure that products meet customer requirements.

The designer team has professional design capabilities: Our designer team has professional design capabilities to provide customers with innovative silicone mold design solutions to ensure that products are unique.

Continuously improving the silicone molding process to provide customers with higher quality services and products: We continuously improve the silicone molding process and technology to improve product quality and enhance customer satisfaction.

FAQ:

Q: What is the minimum order quantity for silicone injection molds that you need to provide?

A: We do not have a minimum order quantity limit, but we suggest that you communicate with us before placing an order to better meet your needs.

Q: What is the manufacturing cycle of your silicone injection mold?

A: The manufacturing cycle varies depending on the product, usually between 20 and 40 days. At the same time, we also optimize the production plan based on customer needs.

Q: How do you ensure the accuracy and size of silicone injection molds?

A: We use high-precision measurement tools for testing to ensure that the accuracy and size of the silicone injection mold meet the requirements.

Q: Can your molds be mass-produced?

A: Yes, our silicone injection molds can be produced on a large scale and ensure stable quality.

Q: What is your process flow like?

A: We adopt a refined process flow, including CAD design, CNC machining, electric discharge machining, wire cutting, polishing and other links.

Q: What type of silicone injection mold can you produce?

A: We are capable of producing various types of silicone injection molds, including seals, insoles, rubber products, electronic product casings, automotive accessories, etc. Personalized design and customization according to customer requirements.

|

|